Plastics Blow Oven

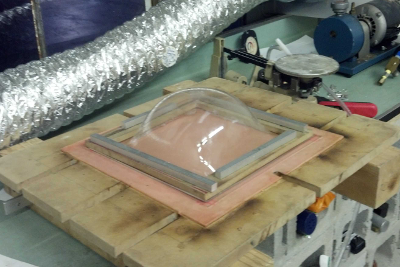

Optically clear bubbles can be made from acrylic sheet by heating it and blowing it through an aperture. I have experimented with a range of different types of ovens and have found that good results can be achieved from all.

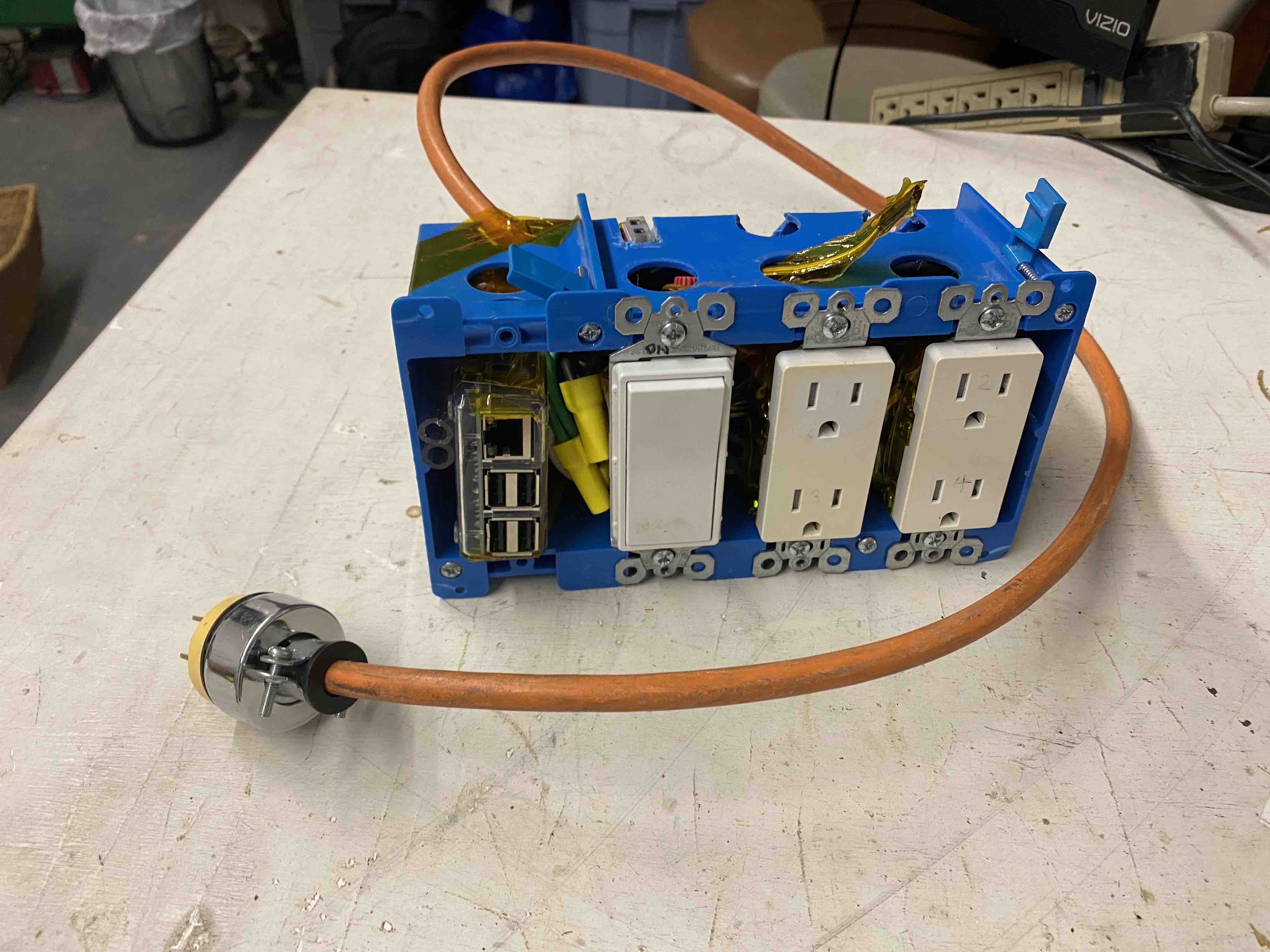

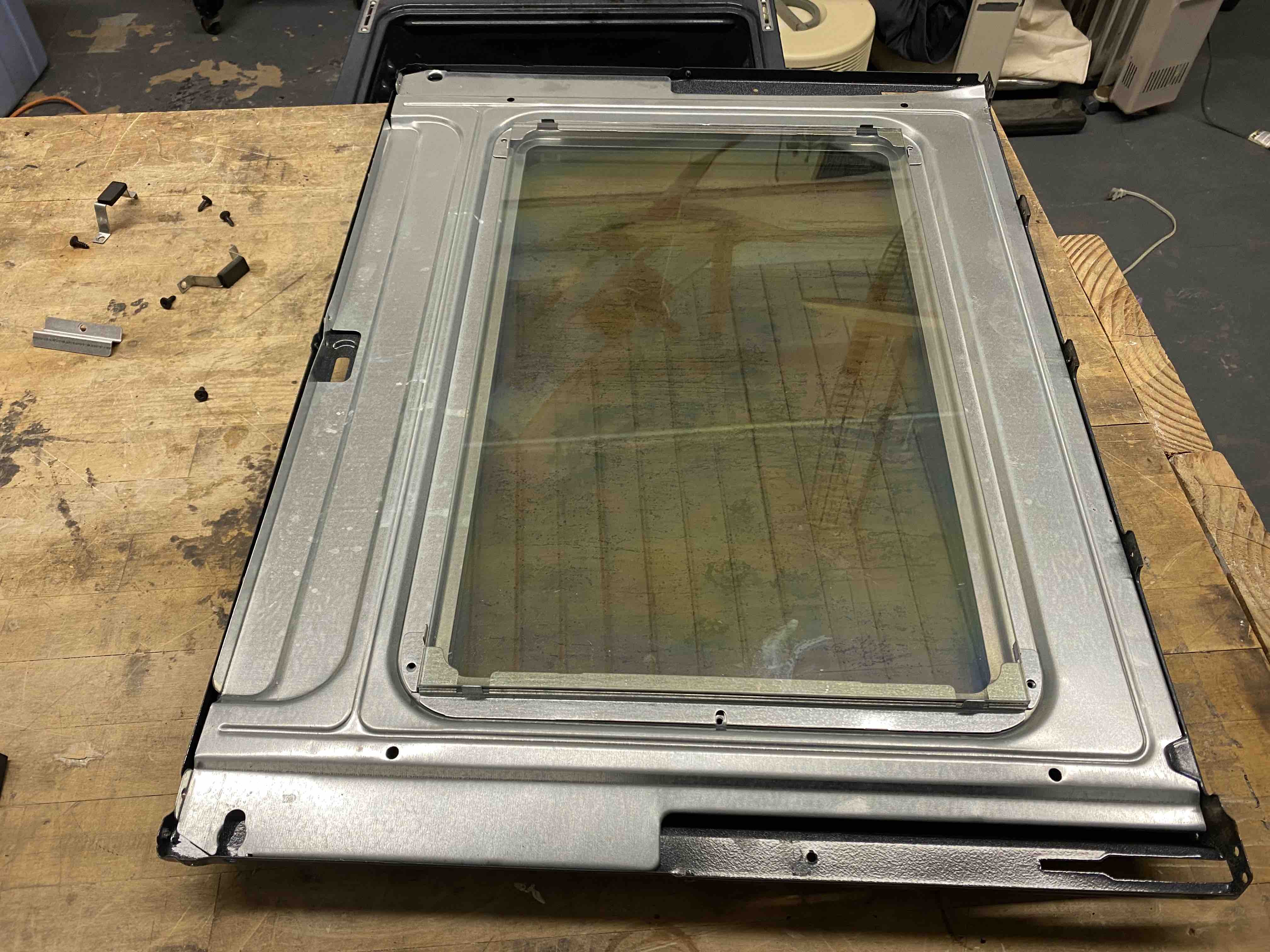

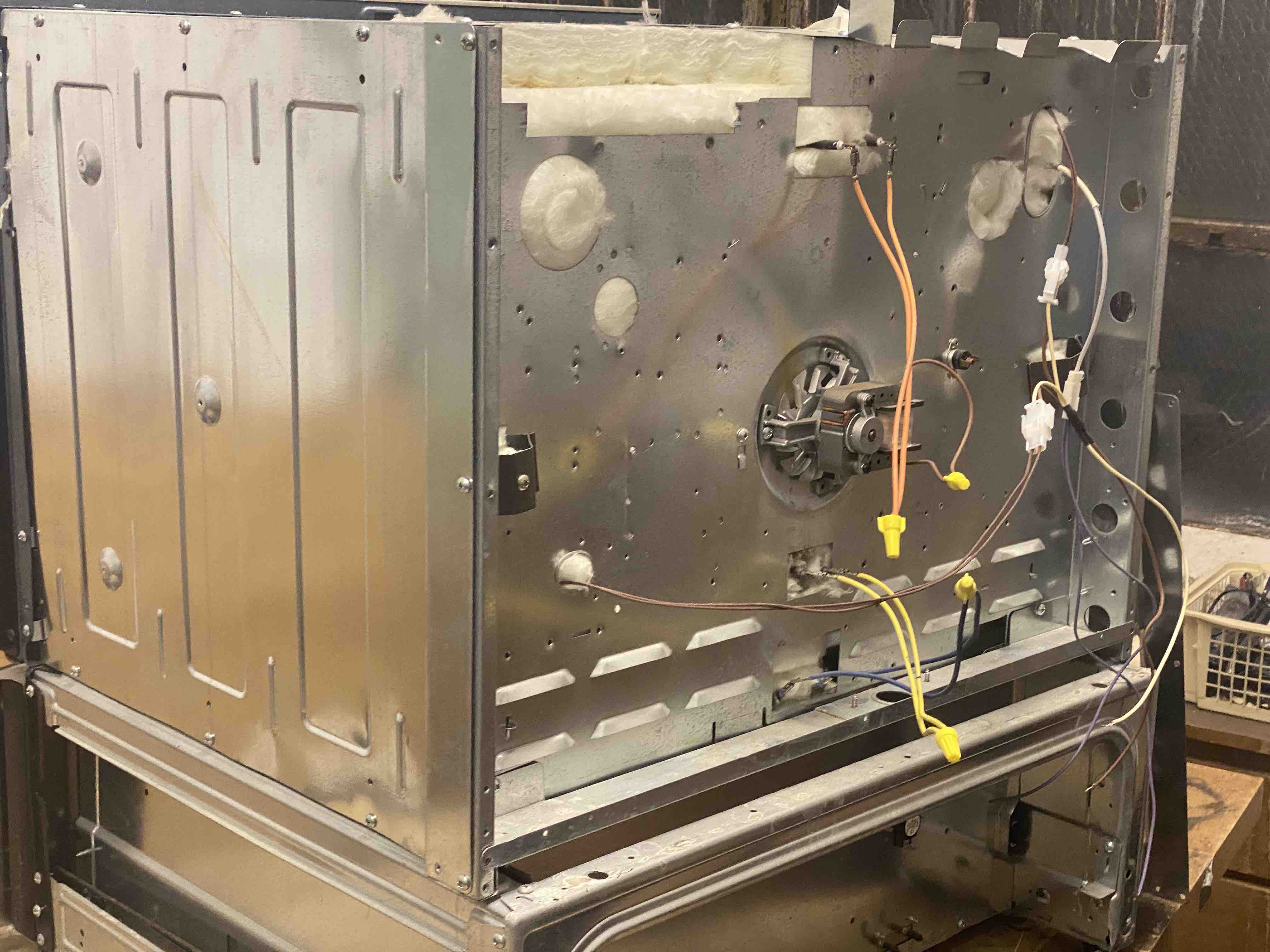

Currently, I am using a residential oven that I hacked to control the coils and added a compressed gas line for thermoforming within it. The same techniques can be used for other types of plastic sheet, and if the bubbles do not need to be too deep, they can be slumped without pressure

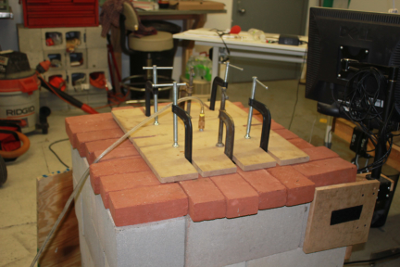

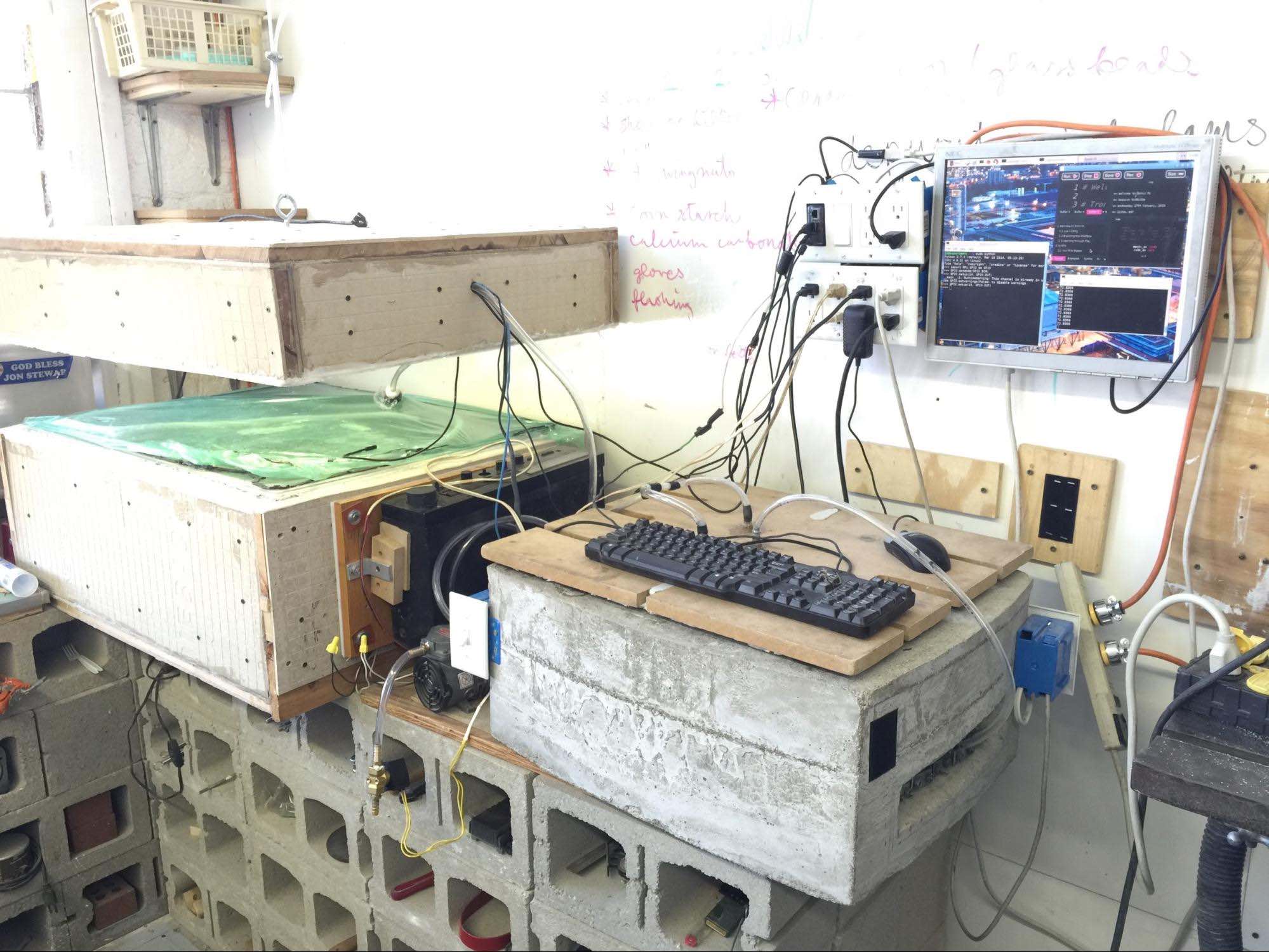

The first oven I used for blowing bubbles was made out of cinder blocks and used propane. I later upgraded to using Kanthal wire as the heating element. The lid of the oven was made from MDF and silicone, and doubles as the holder for the acrylic being blown. The oven can be scaled up by increasing the amount of CMUs and the size of the lid.

Subsequent versions of the oven were made out of concrete, cement board, and aluminum, but now I use a residential oven that I hacked to control the coils independently, and installed copper pipe for compressed gas or vacuum inside the oven.

Here's the original Hackaday Project page: Plastics Blow Oven